About Huarui

Our plywood machinery is engineered for exceptional reliability and precision, enabling customers to enhance production efficiency and consistently deliver high-quality plywood, we strive to be a trusted partner in modern plywood manufacturing.

Make Enclosures to Connect and Protect

From core rotary lathes to energy-efficient veneer dryers, from advanced panel jointing machines to high-capacity hot press machines, every machine reflects our pursuit of engineering excellence and long-term performance.Our Values and PurposeWe believe in powering the future of plywood manufacturing with reliable, innovative machines. By helping our customers boost efficiency and quality, we don’t just build equipment—we build lasting partnerships and stronger businesses.Together, we’re shaping a sustainable plywood industry that creates real value for today and generations to come.

Mission

Vision

Values

What Drives Us Forward

We Stand With Makers

We understand the real needs of factory floors—machines aren’t just tools; they are what you rely on through long working hours, the backbone of your quality promise to customers, and the key to profits and business growth.

Quality That Works, Not Just Looks

Our machines aren’t built to impress in brochures—they’re built to perform under tough industrial conditions. Each unit is tested to withstand time, raw materials, and real-world operation by your team.

Efficiency is the New Value

Efficiency isn’t about working longer—it’s about working smarter. Our machines help you cut costs, save energy, reduce labor, and increase output—so every panel is produced faster, more accurately, and with less waste.

Partnership Is a Long-Term Game

We aim to be more than just a machine supplier. We want to be the partner you think of first when it’s time to expand, upgrade, or transform your production line.

Our Leadership

Jiangsu Team

Factory Team

Why Choose E-able

20+ years of electrical enclosure manufacturing

High-Quality Standards

OEM/ODM designs tailored to needs

Precision production with modern technology

Serving 30+ countries worldwide

Sustainability Commitment

Streamlined supply chain, on-time shipping

Expert support and after-sales assistance.

High-quality solutions at cost-effective rates

Reliable partnerships with industry leaders

Why Choose Guoyu

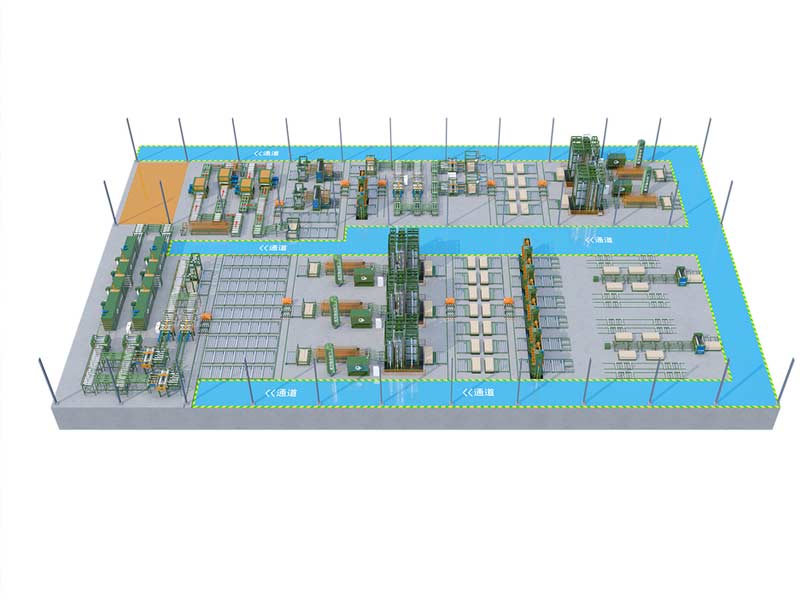

Manufacturing Facilities & Technology

Our manufacturing facility is equipped with state-of-the-art CNC machining centers, automated production lines, and high-precision testing instruments to ensure uncompromising quality at every stage. From raw material processing to final assembly, every step is governed by strict quality control protocols and international standards.

Backed by a skilled R&D team and decades of industry experience, we continuously innovate to enhance machine performance, reduce energy consumption, and improve production efficiency. Our control systems integrate intelligent automation features such as PLC control, HMI touch panels, real-time monitoring, and fault detection.

Committed to sustainability, we incorporate energy-efficient motors, biomass heating systems, and waste heat recovery solutions to help clients reduce their environmental footprint and operating costs.

Whether for high-volume rotary veneer production or customized plywood solutions, our machines are engineered for durability, precision, and long-term value — empowering plywood manufacturers worldwide to build greener, smarter, and more profitable operations.

Customers We Work With

New Factory Setup Customers

We make the complete plan for all equipment, factory layout, and process guidance, covering everything from log processing to drying and hot pressing. we also supply professional process guidance and technical support to help you quickly master production techniques and start plywood production.

Capacity Expansion Customers

We can assess your current production and plan effective capacity upgrades, recommend and supply updated machines for expanded production lines to improve efficiency and energy-saving solutions to lower costs

Local Agents and Distributors

We offer our local agents and distributors reliable, high-performance plywood machines built with innovative technology and strict quality standards. By providing full technical support, training, and flexible partnership terms, we work closely with our partners to grow the local market together.

Replacement Buyers

We can supply new, efficient, and easy-to-maintain plywood machines designed to outperform old or unreliable equipment, helping customers reduce operating costs and improve productivity.

Sustainability

We design our plywood machines to help customers save wood, reduce energy use, and build a more sustainable production process. Our equipment allows small-core rotary cutting, precise veneer sizing, and accurate edge trimming — so you get more usable material from every log. Wood scraps and offcuts can be reused as fuel, turning waste into energy. We also provide veneer jointing machines to help you make use of smaller pieces that would otherwise be thrown away.

Our energy-saving dryers use advanced heat exchange systems, variable speed fans, and waste heat recovery to lower fuel costs and cut emissions. All machines are built with strong, long-lasting parts and modular structures for easy maintenance and long-term use. We also include dust collectors and gas filters in our drying systems to keep the air cleaner and the environment safer.

With smart design and practical solutions, we support plywood producers who care about efficiency, cost savings, and sustainability.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

Get More Benefits Since Submit The Info Form

*We respect your confidentiality and all information are protected.

Get More Benefits Since Submit The Info Form

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

Company News

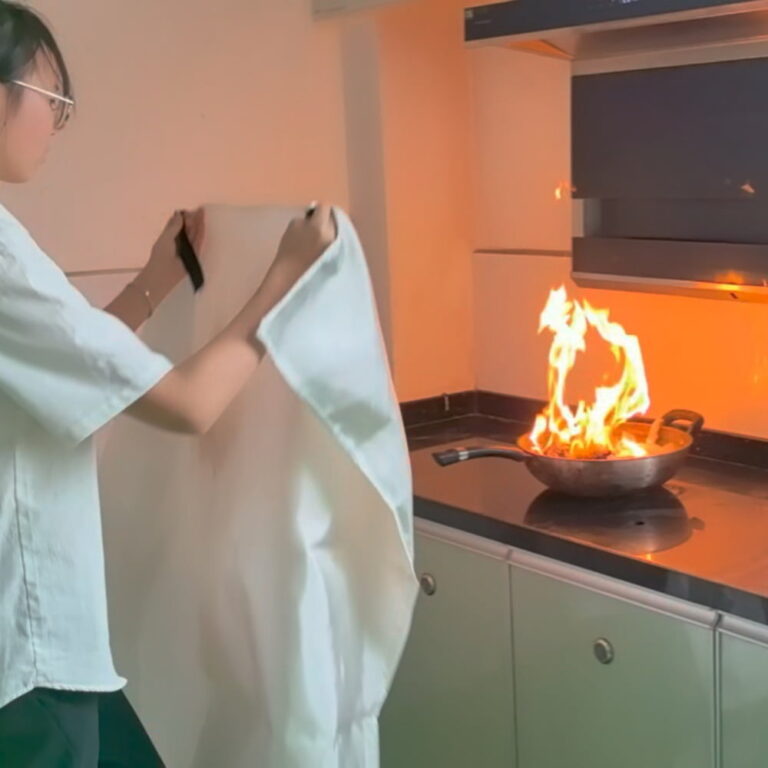

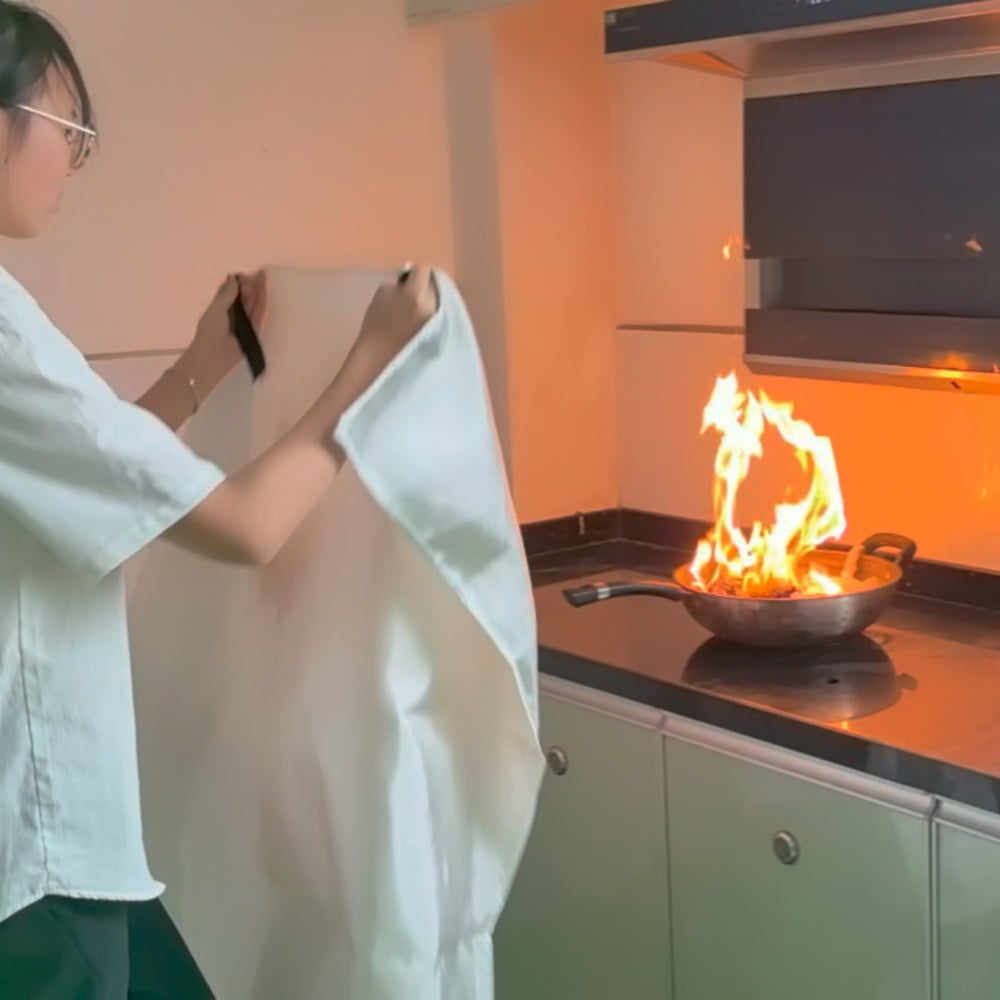

Warehouse Fire in Highlights the Importance of Industrial Fire Blankets

A warehouse fire recently

Tehran Bazaar Fire Highlights the Importance of Fire Blankets in Public Markets

A large fire recently bro

2026 Vehicle Recall Alert: Why Your Facility Needs an Automotive Fire Blanket Now

Massive 2026 Vehicle Reca

Warehouse Fire in Highlights the Importance of Industrial Fire Blankets

A warehouse fire recently

Tehran Bazaar Fire Highlights the Importance of Fire Blankets in Public Markets

A large fire recently bro

2026 Vehicle Recall Alert: Why Your Facility Needs an Automotive Fire Blanket Now

Massive 2026 Vehicle Reca